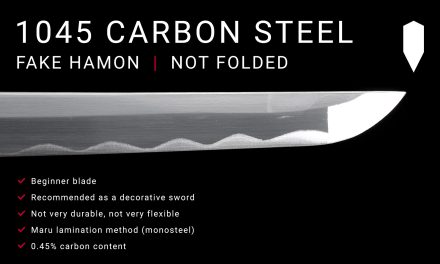

For those Purchasing a Katana for the first time, the question arises, “Which blade steel is best for a katana?”.

In this article, we want to introduce you to the different types of steel used for katana, focusing specifically on the blade types that we offer.

Which Blade Steel Is the Best?

The type of steel and the treatment are crucial for the quality of a katana blade; however, the best blade is not always the best choice for the buyer. For example, a beautiful, high-quality decorative katana doesn’t need an expensive blade for cutting sports, as a decorative katana is not intended for regular and rough use.

However, anyone looking for a katana for regular practical use (such as test cutting / “tameshigiri”) should pay close attention to the quality of the blade when purchasing.

When it comes to cutting sport katana, opting for a clay tempered blade over one without clay tempering is always the better choice.

Damascus steel (folded steel) serves a purely aesthetic purpose today (beautiful grain pattern). The folding process has no impact on the blade’s quality with modern steel.

A Closer Look at Our Blades

Below is an overview of our various katana blades. The price difference of the blades also results from elaborate treatments of the blade by hand, which are not all explained in detail here. All blades mentioned here can also be used in our Custom Katana.

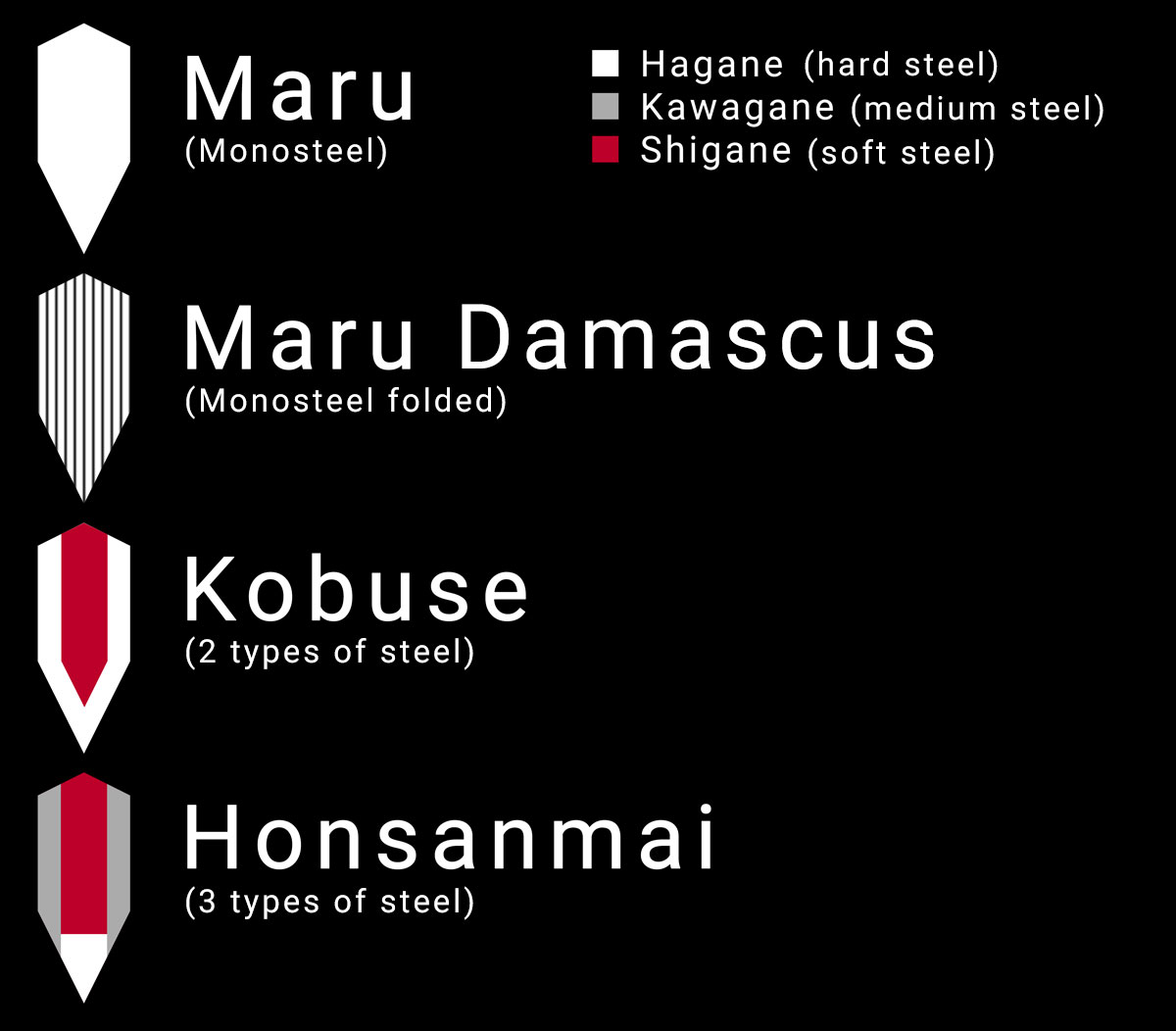

Lamination Method of Katana Blades

The construction of a Katana blade, also known as the “Lamination Style,” played a crucial role during the time of the samurai in determining the sword’s durability, flexibility, and cutting ability.

In the past, the Kobuse and Honsanmai constructions were popular as they provided greater durability and performance. However, in modern Katana, the Maru construction is often preferred, where a single high-carbon steel type is used. This method is simpler to produce, and the quality of modern steel is so high that even monosteel blades are very durable.

Due to the quality of today’s steel, Maru blades are an attractive option for many practitioners and collectors.

Here, we introduce three main types of blade construction, which are also available for our custom Katana:

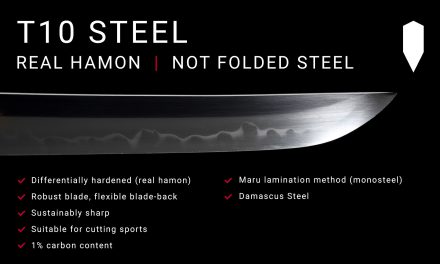

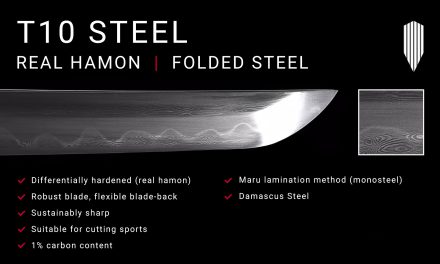

- Maru: These blades are made from a single type of steel (monosteel). Thanks to modern steel quality, monosteel blades today are of high quality and are hardly distinguishable from more complex blades. We also offer Maru blades in folded steel (Damascus steel).

- Kobuse: This method uses two types of steel – a hard steel for the edge and a softer one for the core.

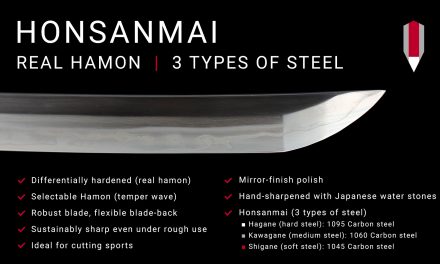

- Honsanmai: This advanced technique combines three types of steel and is mainly used for high-end Katana, which require maximum performance and durability.

Choosing the Right Blade Steel for Each Katana Type

Here you will find our recommendation for choosing your katana blade. A clay tempered blade always performs better than a blade without clay tempering. Folded steel (Damascus) has a purely optical effect.

Deco Katana

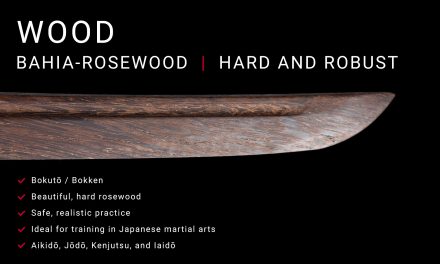

The choice of blade does not matter here. If you want a beautiful grain pattern on the blade, choose a blade made of folded steel (Damascus) here.

- Stainless Steel

- 1045 Carbon Steel

- 1060 Carbon Steel

- T10 Carbon Steel

- 1095 Carbon Steel

- Kobuse

- Honsanmai

Practical Katana

Katana with these types of steel are sharp and robust, ready for practical use.

- T10 Carbon Steel (clay tempered)

- 1095 Carbon Steel (clay tempered)

- Kobuse (clay tempered)

- Honsanmai (clay tempered)

Cutting Sport Katana

Sustainably sharp blades even in rough use. Hard yet flexible blade. Ideal for tameshigiri.

- 1095 Carbon Steel (clay tempered)

- Kobuse (clay tempered)

- Honsanmai (clay tempered)

Folded Steel (Damascus) or Not?

Folded steel is easily identified by its beautiful grain pattern (hada). Katana with blades made of folded steel (Damascus) are closest in appearance to traditional samurai swords (nihonto).

A Damascus blade offers a purely aesthetic advantage.

As for the quality of the blade, the folding process has no effect on modern steel. The folding process neither improves the hardness nor the performance of a katana.

We offer the “Damascus” option with the following blade steel:

- 1060 Carbon Steel

- T10 Carbon Steel (clay tempered)

- 1095 Carbon Steel (clay tempered)

Clay Tempered or Not?

In the specialized process of clay tempering (also called differential hardening), the blade’s edge is coated with clay before heating, creating a thin layer of clay on the edge. The rest of the blade is painted with a thicker layer of clay. As a result, during cooling (in oil or water), the blade’s edge cools down quickly, while the spine cools down slowly. The outcome is a more resilient steel where the blade is very hard, and the rest of the blade remains soft and flexible.

A clay tempered blade is both hard and flexible.

The resulting temper line (transition from soft to hard steel) is called Hamon. The hamon therefore also indicates whether the blade has undergone the process of differential hardening or not.

More Information on the Katana Blade

– What is a Clay Tempered Blade?

– Hamon – the Temper Line of a Katana

– Folded Steel or Not?

Katana from our shop:

Katana “Doragon no Hi”

Katana “Kogane no Doragon”

Katana “Mitsuri”

Katana “Roiyaru Tonbo”