Tamahagane steel is a traditional type of Japanese forging steel that has been used for centuries in the production of Katana and other swords. The name Tamahagane translates to “precious steel”, which signifies the exceptional qualities of the material.

Blades Crafted from Tamahagane Steel

Tamahagane steel is made from iron sand, which can be found in rivers and mountain streams in Japan. This iron sand is processed into pig iron through an complex procedure and further refined through forging and folding. Throughout this process, the carbon content of the steel is carefully controlled and adjusted to achieve the desired characteristics.

“The sword is the soul of the samurai.” – Yamaoka Tesshu

In the past, the production of Japanese Swords relied almost exclusively on Tamahagane steel, as Japan lacked alternative sources of high-quality forging steel for an extended period. Nowadays, however, there are other high-quality steel varieties suitable for crafting katana. Nevertheless, swords with blades made from Tamahagane steel still hold a special charm, as they are an integral part of Japanese forging tradition and carry significant symbolic value for many

How Is Tamahagane Steel Made?

Tamahagane steel was traditionally made in Japan and is renowned for its unique quality and hardness. The production of Tamahagane steel involved a special process where various types of iron and steel products, such as magnetite, limonite, and coke, were mixed together and placed in a furnace. During the melting process, the steel and iron mixture was layered several times to increase carbon content while simultaneously removing the rest of the metal. The end product was a crude but high-quality steel that could then be forged into a blade by a smith. The production of Tamahagane steel was a complex process that required a great deal of experience and expertise and is no longer common today.

Today, most katana are made from other high-quality steel types like 1095 carbon steel or T10 steel.

Video Tip: Forging a Katana

Here’s an excellent documentary about the samurai’s sword, where the making of Tamahagane steel is also documented:

Why Is Tamahagane Steel so Expensive?

Tamahagane steel is very expensive due to its manufacturing process and the limited availability of raw materials. Producing Tamahagane steel requires a special method to create low-carbon steel, where the iron ore is melted in a charcoal fire for several days, and then hammered and folded multiple times to remove impurities and carbon. This process not only demands specialized skills and knowledge but also a considerable amount of time and energy. Moreover, the raw material, iron sand, is not easy to procure.

“Tamahagane is a very high-quality and rare steel, produced by only a few masters in Japan.” – Hiroko Koshino

Due to these factors, Tamahagane steel is significantly more expensive compared to other steels used in modern times, even though a Tamahagane blade is not necessarily sharper and more durable than a blade made of modern steel.

Is Tamahagane Steel Better than Modern Steel?

Naturally, the quality of a blade depends not only on the type of steel used but also on the craftsmanship, the hardening process, and the grinding technique. A well-forged katana made from modern steel, such as 1095 carbon steel, can certainly demonstrate excellent cutting performance and durability. In comparison, Tamahagane steel is somewhat softer, which carries some disadvantages. Nevertheless, there are still some collectors and buyers who prefer a Tamahagane katana due to its unique manufacturing method and its history, which grants it a special aura. Some reasons why collectors and buyers might still prefer a Tamahagane katana are:

- Tradition: Tamahagane steel has a long history and is closely linked to samurai culture. The forging of a Tamahagane sword requires a tremendous amount of craftsmanship and knowledge, passed down from generation to generation.

- Uniqueness: Due to its production method and the materials used, Tamahagane steel is unique. It is impossible to create exactly the same steel twice, making each Tamahagane sword a one-of-a-kind piece.

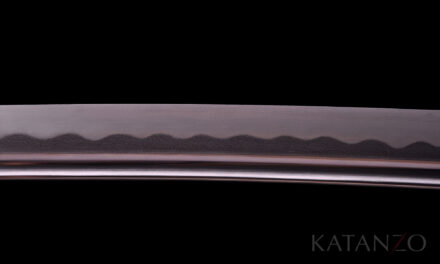

- Aesthetics: Tamahagane steel features a natural grain and shading, giving it a distinctive appearance. Many collectors and buyers appreciate the beauty of a Tamahagane sword, viewing it as a piece of art.

Overall, there are solid reasons to use both modern steels and Tamahagane steel, depending on the specific requirements of the sword and the personal preferences of the collector or buyer.

Final Thoughts on Tamahagane Steel

In summary, it can be said that Tamahagane steel has a long and fascinating history. Although Tamahagane steel is not necessarily better than other high-quality types of steel nowadays, it remains a popular choice for some collectors and enthusiasts.

At KATANZO, we offer a variety of katana equipped with blades made from various types of steel, including Tamahagane steel, 1095 carbon steel, and T10 steel. Each type of steel has its own merits and demerits, and it depends on the characteristics you prefer in your katana. Our team of experts is happy to assist you in choosing the right katana for you. Visit our Katana Shop and discover our collection of handmade katanas or create your Custom Katana from hundreds of individual parts yourself.

Additional Information and Links

- Katana Blade: Steel Types Explained

- What is the Meaning of “Full-Tang” with Regard to Katana?

- What is Clay Tempering?

- Folded Steel or Unfolded?

Katana from our shop:

Katana “Doragon no Hi”

Katana “Kogane no Doragon”

Katana “Mitsuri”

Katana “Roiyaru Tonbo”